Quality Assurance

TOOLS:

» Metallographic Sample Preparation Setup :

» Abrassive cut off machine (Medium)

» Abrassive cut off machine (Upper medium)

» Surface grinder machine

» Hot mounting press for moulding of intricate shape samples.

» Double disk variable speed polishing machine.

» Abrassive cut off machine (Upper medium)

» Surface grinder machine

» Hot mounting press for moulding of intricate shape samples.

» Double disk variable speed polishing machine.

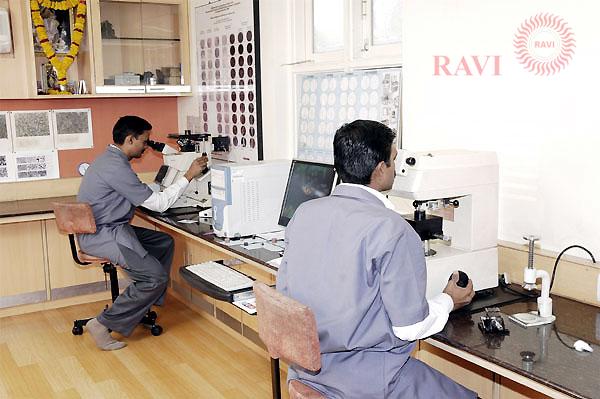

» MIC Image Analyzer :

Image analysis is done for critical cases. MIC software installed, covers various metallurgical spects like-

» Volume fraction ( ASTM E-562)

» Graphite Morphology ( JIS 5502)

» Inclusion Rating (ASTM E-45, ASTM E-1122, JIS G0555, IS:4163)

» Delta Ferrite

» Grain size

» Linear Measurement

» Powder Particle size & distribution and others

» Microscope :

Microscope is the most important tool for one, who is dealing with metals & its processes. OLYMPUS inverted Microscope is our prime tool to study the microstructure of various ferrous material parts. OLYMPUS digital camera DP-12/DP21 is attached with the Microscope for digital photomicrography.

» Microhardness Tester :

We have installed Microhardness Tester (SHIMADZU – Japan) for metallurgical investigation during final inspection & process set up.

» Vickers Hardness Tester :

We have installed Vickers Hardness Tester for metallurgical investigation.